x

Showroom

Medium duty and heavy duty Airless Spray Painting Equipments are wonderful options to apply coatings, paints, primers and putty without creating mess. These user friendly systems are accessible in different capacity based choices.

Electrical Spray Painting Machines are well known for their high speed operation. Run by 2.2 hp motor, these sprayers maintain 227 bar of operating pressure. These spray painting systems have 3.6 lpm flow rate for high speed spraying of coating.

Run by single phase power supply system, this range of wall painting machines deserves praise for its energy efficient 1.5 hp motor, up to 227 bar of operating pressure and high automation degree. Low operating cost is one of the key aspects of these systems.

Wall putty spray machines are used for effective applying of plaster, drywall gypsum, primer etc. These user friendly machines can run for 8 hours continuously without generating any heat. Long working life is one of their main aspects.

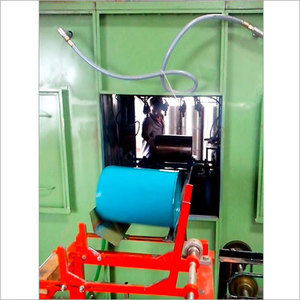

Automatic Painting Systems are used for effective painting of drums and pipes. Run by electricity, these automatic systems maintain specific linear speed and operating pressure. Low operating cost is one of their main aspects.

Airless Dispensing Equipments are used for spraying and extruding adhesive materials, insulation and sealing products. These systems can handle high viscosity fluids. High output pressure and low operating cost are the key aspects of these equipments.

Plural Component Systems are suitable for homogeneous coating of more than one coating materials. These systems can perform blending of coatings in different proportions to attain desired result. These systems are user friendly and these have low maintenance cost.

Airless Assisted Pumps are required for applying coal tar epoxy paints without creating mess. These heavy duty pumps are useful for applying semi solid coatings, primers and coatings of different viscosity ranges.

Paint Agitator/Stirrers are well known for their high speed stirring mechanism that helps to achieve homogeneity in blending. Made of stainless steel, this product range can be availed in different weight and stirring capacity based choices.

Paint Transfer Pumps are used for feeding of filtered paint for spraying guns. These pumps are offered with easy to adjust nozzle. These are installed on caster wheels for their smooth shifting.

Pressure Feed Containers are accessible in different production capacity based choices. These systems are offered with pressure gauge, safety valve and pressure regulator to maintain their accuracy level. These low maintenance systems are user friendly by mechanism.

Jaguar Portable Heavy Duty Airless Painting Machines are effective options for applying spray based paints. These energy efficient machines are run by powerful pump for their consistent operation. Low operating cost is one of the key aspects of these machines.

Available in different specifications, spray gun accessories function at different operating pressure ranges. These accessories are suitable for handling coatings and paints of various viscosity ranges. Long lasting quality is one of their main aspects.

Stainless steel or aluminum made Diaphragm Pumps are suitable for high pressure based jobs. Compact in shape, these pumps maintain high flow rate of transferred media. Lubrication free mechanism is one of their remarkable aspects.

|

JAGUAR SURFACE COATING EQUIPMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |